In my second post I outlined how any organization can enjoy cost-free improvement in flow most efficiently by using the Five Focusing Steps of Theory of Constraints to manage the constraint that exists in their value stream. This makes it very attractive for both small and medium enterprises that are hesitant to spend upfront a lot of money before getting any payback. Since both Lean and Scrum have been known to work this hesitancy implies that sometimes they don’t. In this post we address the nature of systems that we are interacting with and how the Theory of Constraint framework can help explain why sometimes we encounter problems in our improvement efforts, and how TOC principles are able to achieve PeakFlow© under such circumstances.

Complicated or Complex?

In his book It’s Not Complicated: The Art and Science of Complexity in Business, Rick Nason defined both complicated and complex systems below.

To a scientist – a biologist, for example – a complicated issue is one where the components can be separated and dealt with in a systematic and logical way that relies on a set of static rules or algorithms, such as the laws of physics.

A complex issue is one where one cannot separate out the parts and for which there are no rules, algorithms, or natural laws such as are found in physics.

I think it is safe to say that most systems in both supply chain and knowledge management are both complicated and complex by the above definitions. Solutions like the Waterfall approach, Lean and Scrum work better when the system is mostly complicated: For example, the Lean framework can work well enough for supply chain operations, when we can model it with a line of work centers from supplier to customer, often referred to in 6 Sigma with the acronym SIPOC. For knowledge work such as IT projects, the Waterfall approach was replaced by Scrum with excellent results. In this case, the paradigm shift was the recognition that excessive planning and commitment of resources without customer validation resulted in long loopbacks when the product did not meet actual customer requirements. In both cases of Lean and Scrum, the flow of material or information respectively saw a significant improvement with the removal of work-in-progress and waste.

However, when we are working with complex systems such as a network of work centers, both Lean or Scrum are by design unable to address them well. For example, when scaling from a single scrum team to the multiple scrum teams the Scrum@Scale Guide is short of any advice in this regard. That is not all. Two other forms of complexity such as set-based designs and “lean” startups, cannot be managed well using the standard lean and scrum approaches. On the other hand, the Theory of Constraints framework is robust and can be easily extended to such use cases. With the pace of change in all industries and the focus on knowledge work, the level of complexity is rising continually and we need more robust frameworks.

Theory of Constraints and Complexity

TOC directly addresses the systemic complexity of our processes, with an approach that is agnostic to whatever framework is used. This is attractive again from an implementation point of view: you don’t have to expend additional costs to retrain all your employees again on the latest fad, and you don’t lose engagement with your staff when retraining them all over again. Hence you can safely incorporate the TOC tools into your 6 Sigma DMAIC or DMEDI process, Lean, Scrum, Kanban Method and project management. The tools include Drum-Buffer-Rope (DBR), Fever Charts, and they are part of what is known as Critical Chain Project Management (CCPM). CCPM is the approach used to manage projects and scrum teams at scale, that ensures that interactions between various “paths” or branches of a project are both minimized and smooth out using buffers. The same treatment is applied at the next lower level of granularity between tasks and resources as well, by applying both student syndrome, removing multitasking and other principles. See below for a short description.

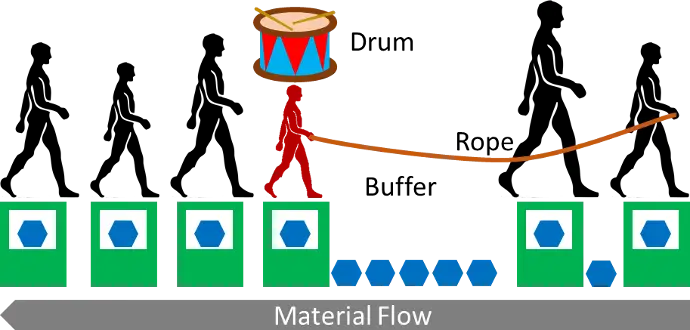

Drum-Buffer-Rope (DBR)

This slaves the input feed rate to that of the elevated constraint, that acts as a drum, while unplanned fluctuations are smooth out with a dedicated buffer before the constraint. How is this different from the “pacemaker” and “supermarket” commonly found in Lean? If you google this topic online, you will realize that there is no definitive means to locate the pacemaker, only some guidelines. Here is an example I found:

In order to effectively implement the pacemaker principle, it is important to carefully select the appropriate process to serve as the pacemaker. This process should be stable, consistent, and capable of producing high-quality products in a timely manner. Link

Likewise, the supermarket is to reduce waste in replenishment. This is important. In TOC the buffer is not just to reduce waste but to ensure the constraint is running as fast and consistently as possible, as we want to maximize our flow rate. We ensure the buffer levels support this, and it also acts as a leading indicator of system performance.

The best part is, TOC principles and tools build on your previous improvements since you know the principles behind it, and not a set of rules of thumbs.

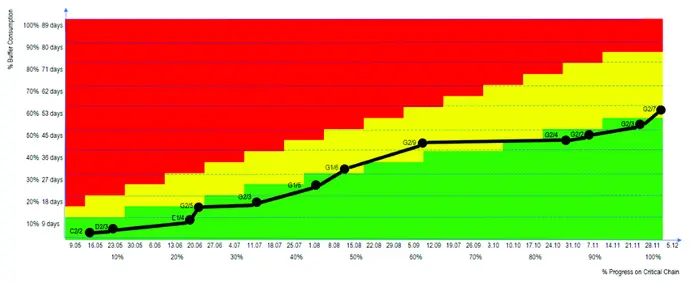

Fever Charts

By dividing the buffer into three zones of green-yellow-red, we are able to provide a leading indicator of the status of the process or value stream. This ensures that all countermeasures are ready to be deployed when required, as well as ensuring that resources are deployed and management is able to get an overview of the program status. Again, it is an upgrade when compared to the burndown charts found in Scrum, and don’t require wholesale change.

If this article has made you curious, get in touch with either Steve Tendon of Tameflow and Wolfram Muller of DolphinUniverse and read their books. Wolfram has a lot of material that goes into the nitty gritty of deploying TOC in any system at his site.

Or, if you are in Singapore interested in deploying the TOC framework in your organization, contact me alvin@peakconsultants.co. I will reach out to you and we can discuss how to deploy the Theory of Constraints framework at your organization for FREE as part of my ongoing research in this topic.